Handling corrosive, toxic and flammable materials needs a special type of pump. When it was time for API manufacturer Ofichem to upgrade its pumping equipment, it found that Almatec® E-Series and CX Series AODD pumps proved the ideal solution.

The Dutch Ofichem Group BV is a developer, manufacturer and distributor of active pharmaceutical ingredients (API) for use in the global human and veterinary-medicine markets.

One of the most dangerous chemicals Ofichem handles is hydrochloric acid, which is highly corrosive and must be handled with extreme care. To that end, because of the toxic, corrosive and dangerous nature of many of the raw materials that Ofichem uses, safety for both site personnel and the environment is an overriding day-to-day concern.

In the large-scale production area, for example, as many as 500 kilograms (1,100 pounds) of solvents, acids or powders will be transferred in a single day, with various liquids also used to facilitate any number of chemical reactions.

Equipment upgrade In 2007, Ofichem was looking to upgrade the pumping equipment at the lab and contacted Gerrit Klaassen, commercial director of Holland Air Pumps, Oirschot, The Netherlands, for some recommendations.

“If you look at safety issues, our highly toxic products are kept in special areas, things like carcinogenics that cause cancer,” said Remco Vree Egberts, R&D manager and project leader for the Ofichem Group. “Also, if there happens to be a fire, we mandate that the area should be enclosed for at least 60 minutes.”

“For me, it was obvious that Ofichem needed a safe pump in this environment, one that has no leakage,” said Klaassen. “A plastic pump that is easily cleaned and has no corroding parts would be ideal for the application.” Handling corrosive, toxic and flammable materials is a fact of daily life at the Lab Ofichem facility, which is why it is critically important that the correct type of pump be identified and incorporated into the production process.

Wim Ekkelkamp is Ofichem’s technical manager and the man responsible for purchasing the pumps that are used in the Lab Ofichem production facility.

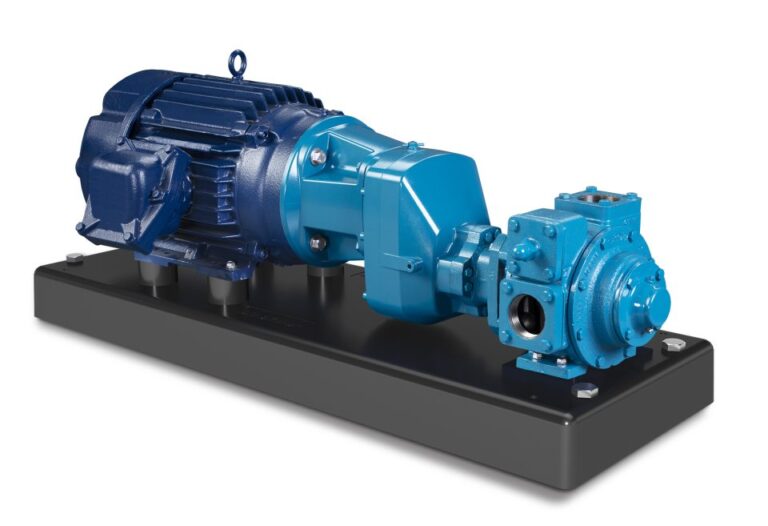

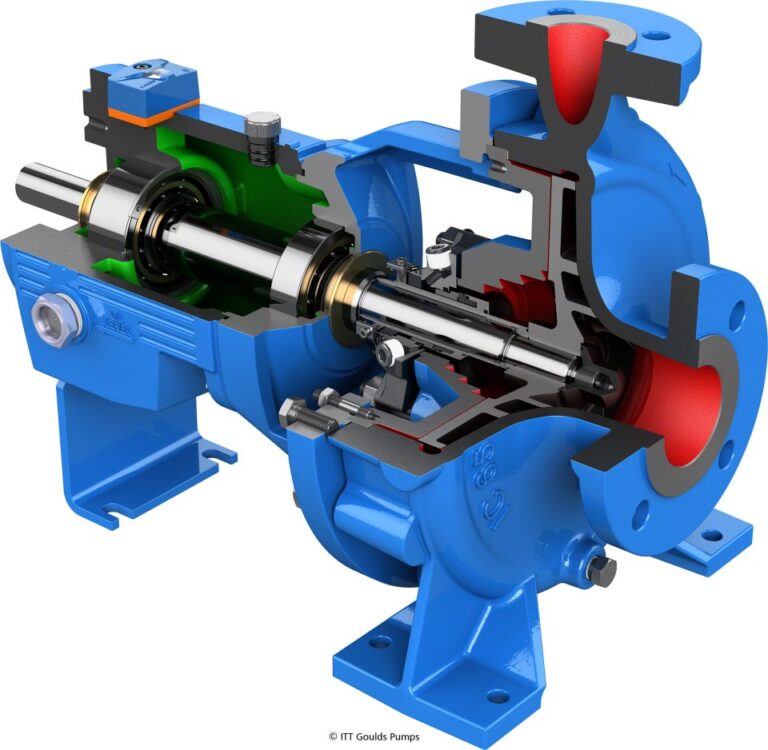

Ideal solutions As it happens, Holland Air Pumps is a distributor of air-operated double-diaphragm (AODD) pumps from Almatec®, Kamp-Lintfort, Germany. In analyzing Ofichem’s API-production setup, Klaassen determined that the Almatec E-Series and CX Series AODD Pumps would be the ideal solutions. E-Series and CX Series pumps are made of solid-block PE conductive material and rated for use in explosion-protected areas as they meet the ATEX requirements of European Directive 94/9/EG regarding the use of equipment or systems in potentially explosive atmospheres.

In terms of operation, these pumps are self-priming and dry-run capable, and possess the ability to empty containers completely. Air consumption and operating cost are optimized through the incorporation of the patented, maintenance-free PERSWING P® air-control system.

“Ofichem chose these pumps because they are reliable, they are very easy to clean, both on the outside and the inside, they are ATEX-certified, which is very important in our production areas, and they have very quiet operation; these are the reasons why we use the Almatec pumps,” said Ekkelkamp.

Low downtime “The thing is, quality is also important, because if you buy a cheaper pump but have downtime of one month every year, then the pump is not cheaper,” added Egberts. “With these pumps we have very low downtime and that’s the most important for us because if our production time is down one day we will lose at least €7,425. That’s why we choose pumps based on quality, not price.”

When the Ofichem Group decided that the time had come to introduce Good Manufacturing Practices to its API-production operation, it knew that this meant that each and every aspect of production would have to operate at the highest level of efficiency and safety.

“We have to keep production moving, we have to keep downtime as low as possible, and we have to be safe, so when we are purchasing any new equipment, the quality is very important,” Egberts said.

So choosing the proper pump technology became a top-of-mind concern for Ofichem’s daily handling many different types of hazardous, toxic, flammable and corrosive chemicals. Any concerns have been assuaged through the incorporation of Almatec AODD Pump technology in its chemical-handling applications.

“It’s very important that our pumps don’t break, that they have solid-block construction and that they don’t have any corrosion,” said Egberts. “If there is any corrosion in the pump, I can’t use it anymore.

We chose the Almatec pumps because they are capable of handling the products we are using. It’s a personal-safety issue — you don’t want any leaks, you don’t want people getting products on them. It’s also a product-safety issue, which in our business is very important. We have been using Almatec pumps for more than 11 years at this facility and we’ve never had a problem with them. We are really happy with them and will continue to use them in the future.”