FPT Industrial, the global powertrain brand of the Iveco Group, has inaugurated its new ePowertrain plant in Turin – and we were there!

The opening of the facility is extremely significant because it’s the world’s first carbon-neutral Iveco Group plant. Measuring 15 000 m2, the plant is dedicated to the production of the brand’s electric range, including electric axles, electric central drives, and battery packs for light commercial vehicles, minibuses, and buses. At full capacity, it will produce over 20 000 electric axles and over 20 000 battery packs per year for LCVs, minibuses, and buses. The plant is ultimately expected to employ about 200 people.

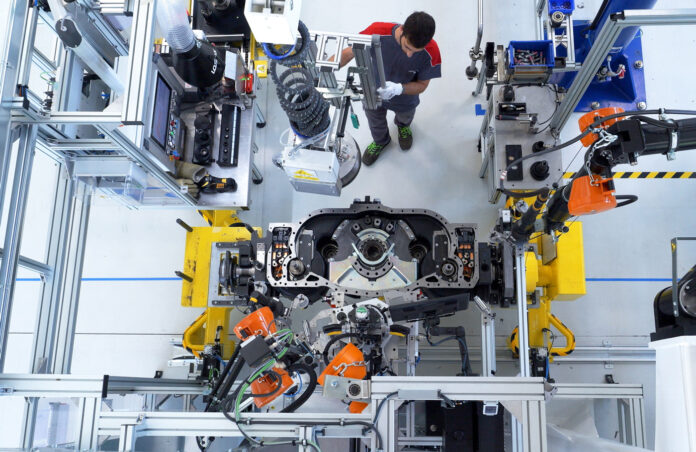

We toured the facility, which looks a bit more like a hospital than a factory; spotlessly clean, the plant has implemented numerous health and safety measures to protect the workers (who are, after all, dealing with high voltages).

Next-generation technologies adopted include augmented and virtual reality (which reduce the design time for production lines by simulating operational outcomes before physical installation); 3D printing and “Smart Observer” systems based on intelligent sensors; 3D scanners for metrology-grade measurements; 3D reality simulators; and cooperative robots. These robots, together with Automated Guided Vehicles, greatly improve ergonomics and safety, making the operators’ jobs easier and less stressful.

Below: Sylvain Blaise, president of the Powertrain Business Unit; Domenico Nucera, president of the Bus Business Unit; Luca Sra, president of the Truck Business Unit; and Annalisa Stupenengo, chief operations officer of the Iveco Group, participated in a panel discussion at the official opening of the plant.

The state-of-the-art factory has implemented numerous health and safety measures to protect the workers. No heavy lifting is required, for instance.