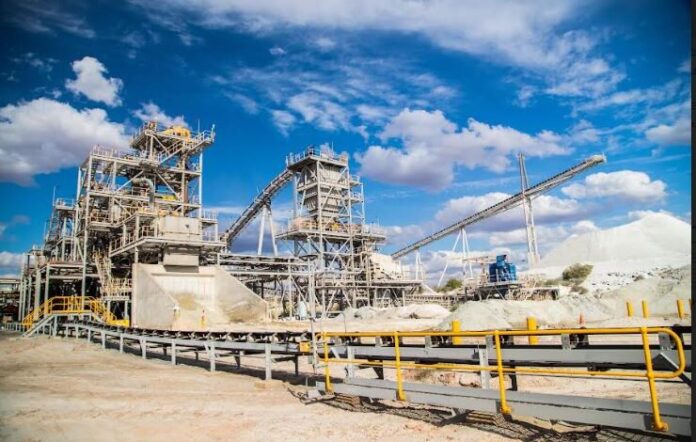

TOMRA Mining’s unique experience in the design and installation of large-scale ore sorting plants and its collaborative approach was the key to the successful design of the world’s largest lithium sorting plant. The installation has already started and is expected to reach completion in late 2023.

Pilbara Minerals owns the world’s largest, independent hard-rock lithium mine. It is located in Western Australia and produces a spodumene and tantalite concentrate. By pursuing a growth strategy to become a sustainable, low-cost lithium producer, the company has become a major player in the rapidly growing lithium supply chain. This investment will ensure the expansion of its large-scale operation in order to meet the increasing demand for lithium driven by sustainable energy technologies such as electric vehicles and energy storage.

“This new facility to be constructed at our Pilgangoora Project will be the world’s largest lithium mineral ore sorting plant. TOMRA’s experience in large global sorting installations, innovative technology, and ability to provide local support were significant factors in our decision to work with them. From the start, the TOMRA team has been working side by side with us and our engineering partner DRA Global to deliver this important project” Dale Henderson, Managing Director and CEO, Pilbara Minerals

Processing contaminated ore: a key challenge for the lithium industry

As part of this expansion project, Pilbara Minerals turned to TOMRA Mining for assistance to address the key industry challenge in the processing of spodumene feed ore contaminated with barren host rock. TOMRA has 50 years’ experience in sensor-based sorting technologies and has designed and built 90% of the world’s large-scale mining sorting plants with a capacity above 300t/h. These include plants such as the Ma’aden Umm Wu’al project, which is operating at 1850t/h, or the Lucara diamond operation which runs 15 sorters. Specifically for the Pilbara Minerals project, TOMRA Mining offers effective ore sorting solutions with high sensor resolution and ejection accuracy that ensure high lithium recovery and waste removal with a stable and consistent performance at high capacity.