With its well established design and manufacturing capabilities in South Africa, Sandvik Rock Processing delivers customised and standard vibrating equipment solutions, including screens and feeders, to customers that enhance future flexibility.

Gideon de Villiers, Engineering Manager at Sandvik Rock Processing, says the company has built its success on decades of field experience – and the nurturing of its mechanical and metallurgical engineering skills base. Its 21,000 m 2 facilities, in Johannesburg South Africa, house modern workshop and testing facilities that are ISO 9001:2015 accredited and produce world class solutions for global markets.

“A key aspect of our design philosophy is to ensure that our customers can be more agile when their operational demands change,” says De Villiers. “This allows cost effective modifications to be made relatively quickly, without unduly disrupting production.”

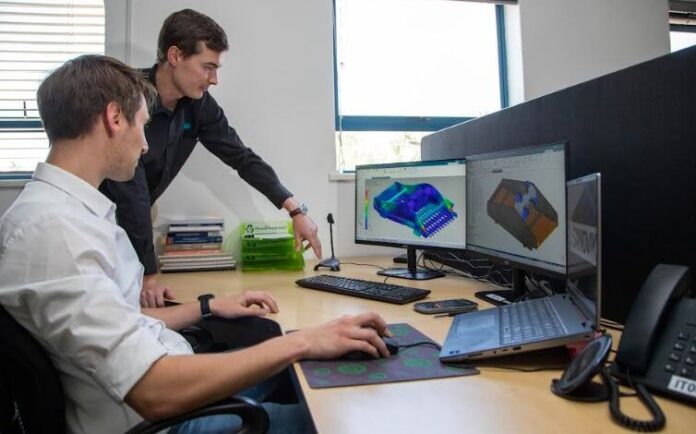

In-house engineering

He emphasises that this is possible due to the depth of vibrating equipment related expertise that the company has developed, where in-house mechanical and metallurgical experts can come together to find screening and feeding solutions. It is also thanks to the far-sighted initial design of Sandvik Rock Processing’s screens, which carefully take into account the opportunities for future modification.