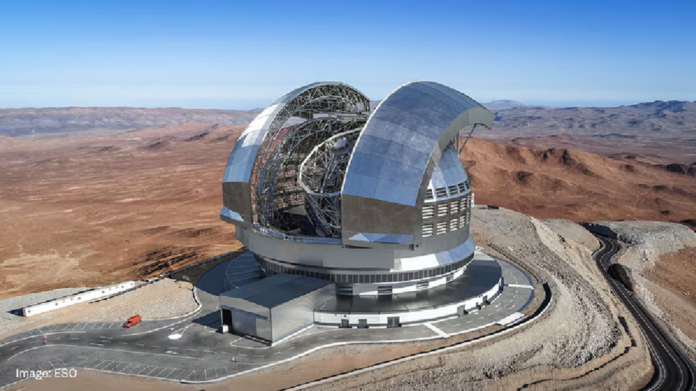

Adjustable chocks from SKF will play an important role in the world’s largest visible/near-infrared telescope, the ELT, which is currently under construction in Chile

An unsung product from SKF’s catalogue – the adjustable chock – has played a key role in the construction of a huge telescope.

The European Southern Observatory’s Extremely Large Telescope (ESO’s ELT), now being built in Chile, will be the world’s largest visible/near-infrared telescope on completion in 2028. Its 39m-wide main mirror comprises 798 separate hexagonal pieces, attached to a base structure using steel flanges and SKF Vibracon adjustable chocks.

“Each flange sits on four adjustable chocks,” says Marco Colussi, a structural engineer at Italian engineering firm Cimolai, which is responsible for assembling the mirror. “The ability to readjust each mirror segment is key to the success of the telescope.”

Each low-profile Vibracon unit typically allows up to 12 mm of adjustment. However, the application needed up to 15 mm of adjustment – meaning several design tweaks were needed.

First, Cimolai inserted extra washers, allowing the adjustment range to be extended to 15 mm. This had to be performed with a positioning accuracy of tenths of millimetre, across the 39 m span of the mirror. The chock also had to fit into a limited design space – which was restricted to 25 mm in height.

In addition, the chocks were installed upside-down, to help Cimolai meet the stiffness requirements of the system. The high stiffness helps to reduce the weight of the mirror – which improves the telescope’s stability and performance.

Overall, the main mirror will use more than 9,500 SKF Vibracon SM 16 ELP-ASTR low-profile chocks – 12 for each mirror segment. Chocks are individually surface treated, to give them consistent quality and extend their performance in such a demanding environment.

The ELT will cost an estimated €1.4 billion to build. It will, among other things, search for exoplanets and study early galaxies. Hard to think that, for its vast size and cosmic ambitions, its success will rely partly on adjustable chocks just three inches in diameter.