On many bridge construction projects, cranes are sometimes the best and only option for moving heavy items around a site. But there are many situations when alternative equipment is needed.

The limitations of cranes for bridge construction include:

Poor Accessibility: A generous amount of space is needed to position and operate a crane, which can be difficult in areas with limited access or tight spaces.

Height restrictions: Cranes lift the load from above, so the height of cranes limits their usefulness on projects involving overhead obstacles, such as cables or underneath a roof structure.

Weight restrictions: Cranes have capacity restrictions that can limit their ability to lift very heavy bridge components.

Weather conditions: Strong winds, heavy rain, or extreme temperatures affect the stability and safety of crane operations, making it difficult to work in certain conditions.

Cost: Cranes can be expensive to rent or purchase, and their high operating costs can add up quickly.

What are the alternatives to cranes?

Precise lifting and positioning are crucial during bridge and highway construction. While cranes are the mainstay of many projects, in some cases the use of a crane is impractical or simply too expensive, especially due to the extensive transportation logistics required to get all crane parts to the construction site.

Various alternative lifting systems exist and are proving increasingly efficient, these include:

Hydraulic Strand Jacks: Compact, easy to transport, and powerful enough to lift loads of over 3,000 tonnes without difficulty.

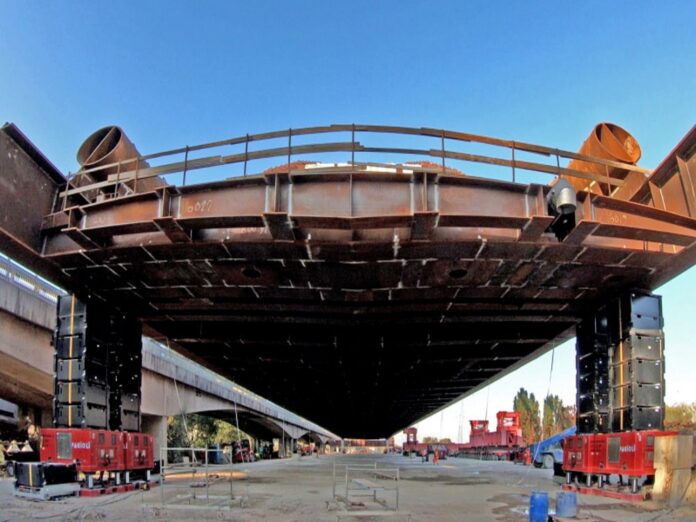

Hydraulic Gantries: Using four or more telescopic legs and beams that allow heavy loads to be lifted vertically, and along a track when required.

Jack-Up Systems: Lifting loads in successive stages using spacers, called “barrels”, stacked together to form lifting towers t0 mechanically support the load.