Eazi Access, is one of Africa’s market leaders in the rental, sales, servicing and training of work-at-height and material handling solutions. We have a strict commitment to safety, reliability, and productivity, across everything we do and in all industries, we serve. We have partnered with trusted OEM’s, JLG and Linde Material Handling, to provide safe working environments.

This is achieved through the different equipment we have on offer. Within the equipment range, we have aerial lifts, boom lifts, scissor lifts, telehandlers, and low-level access lifts ensuring workers are lifted safely and efficiently. Within the industry this lifting equipment is commonly referred to as Mobile Elevated Work Platforms (MEWPs) which have multiple benefits, and are available to our customers on a rental or sale basis.

MEWPs are safe, manoeuvrable and time saving machines used to lift workers into spaces they otherwise would not be able to reach. MEWPs are used on both indoor and outdoor worksites to eliminate the risk of accidents associated with climbing, lifting, and even falling on the job. The need to keep workers safe while accessing high areas is common between many different sectors, making MEWPs versatile and universally needed. They are also flexible between different tasks on the same project. They can be easily adjusted for different heights, and some are even designed for use on smooth and rough terrains.

This makes a worksite more accessible by increasing the workers’ reach, whether they’re in a warehouse, on a mine, on a construction project or at an event. When a customer comes to Eazi Access looking for a MEWP, we invest time in performing a thorough diagnosis before we can recommend the suitable solution. We go on-site where we take measurements and look at the size of the area and fully understand the objectives of the customer for the job at hand. After which, we recommend the best fit solution for the job on-site. We can provide a complete solution for the different industries from the highest machine which is up to 58.56 metres to the smallest scissor lift that can be use in the warehouse.

According to Blaize Wulfsohn, Eazi Access GM: Compliance & Enterprise Risk Management other industry drivers for MEWPs include health and safety as they reduce fatigue and risk, productivity through increased flexibility and efficiency, while technology advances have also led to more reliable mobility and control. Renting MEWPs for hard-to-access jobs can save money by increasing productivity across the worksite.

As a business we are enthusiastic about the safety, efficiency, and cost benefits we can deliver to our customers and we pride ourselves in consistently ensuring that every customer, regardless of industry, size, or scope of needs, receives the highest level of service and professional advice to ensure our customers get the right machine for their specific requirements. One of the ways we ensure safe working environments for our employees and customers is through training and compliance to regulations which is essential in creating safe working environments.

In order to operate access equipment workers are required by law to undertake training. As a business, providing this training is beneficial to both our customers and to our operators

Wulfsohn adds that “our safety promise underscores every facet of our business. Uplift Quality Solutions, our training business, specialises in operator training on mobile elevated work platforms (MEWPs), telescopic boom handlers, forklifts, overhead cranes, and mobile cranes. Customers can choose between having their own operators trained in line with industry standards and manufacturers’ specifications, or we can provide readily available, trained Eazi Access operators to work on-site.”

Eazi Access and our training business, Uplift Quality Solutions are both members of the Institute for Work at height (IWH), which is the recognised industry professional body registered with SAQA (South African Qualifications Authority). Members of the IWH are declared fully competent to practice in a specific field of the Work at height Industry and members have to comply with the IWH Code of Ethical conduct. Uplift Quality Solutions is accredited as a training provider by the IWH and is also registered with full accreditation with the TETA (Transport Education Training Authority). Our association with IWH and our accreditations with the TETA and IWH provides comfort to our customers on the quality standards of our training provided, the quality of equipment used for training as well as the issuing of legitimate IWH training certificates. The IWH training certificates have the advantage of avoiding the delays with issuing of training certificates by the TETA and allows the trainee to start operating the respective equipment soon after the training.

Keeping safety and training topical within the industry is a key target adopted through the years. However, despite the increased training provided, incidents still happen. Also, with newer and improved models being delivered to the market training continues to be crucial for anyone operating a MEWP.

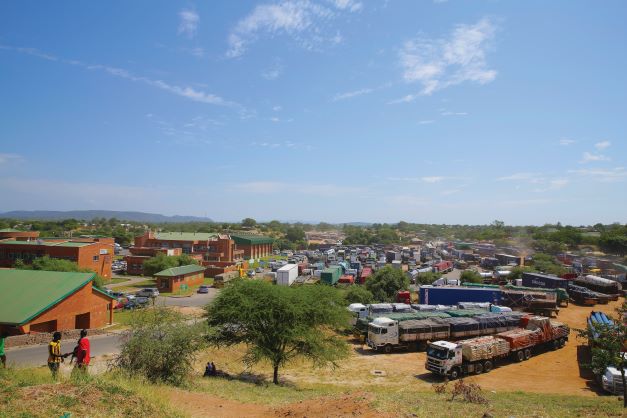

The rising price of copper over the past 18 months and the relaxing of tax liabilities by government for mines had positively impacted mining production and led to increased exports. “At the same time, mines were investing in increasing production capacity, and this automatically impacted on inbound cargo flow within Zambia for capex investments of the mines.”

The rising price of copper over the past 18 months and the relaxing of tax liabilities by government for mines had positively impacted mining production and led to increased exports. “At the same time, mines were investing in increasing production capacity, and this automatically impacted on inbound cargo flow within Zambia for capex investments of the mines.” DSV Zambia is part of DSV – Global Transport and Logistics, which manages supply chain solutions for companies from 90 countries and has been operating in Zambia for 30 years.

DSV Zambia is part of DSV – Global Transport and Logistics, which manages supply chain solutions for companies from 90 countries and has been operating in Zambia for 30 years.