ummer 2009 sees a new challenge to the land speed record for a steam car, ‘Inspriation’. Technology from CAT PUMPS is playing a critical part in this record-breaking attempt.

The three-ton steam-powered car ‘Inspiration’ has enough fuel, compressed air and water to run for three minutes.

The three-ton steam-powered car ‘Inspiration’ has enough fuel, compressed air and water to run for three minutes.

Summer 2009 sees an attempt to break the land speed record for a steam car. Powered by a steam turbine, the car’s 12 boilers need to be carefully primed with demineralised water. CAT PUMPS provided a critical solution to provide continuous forward liquid flow for a smooth operation.

History

Back in 1906, the fastest car in the world was the Stanley Steamcar which set a world record speed of 127 mph at what is now Daytona Beach, Florida. In comparison with today’s production road cars that is a relatively modest speed, but it is an official FIA record that has never been broken by another steam powered car.

In 1985, a similar car powered by a steam turbine car did reach a speed of 145 mph, but this was not recognised by the FIA because it did not comply with their regulations, these being two runs over a measured mile within one hour. Since then, there has not been a serious attempt to set a new record.

The Steam Car Company

In 2009, this 103-year-old land speed record could well be broken as a challenge is mounted by an innovative group of engineers from the UK operating under the auspices of The Steam Car Company. Their attempt with a steam car named ‘Inspiration’, taking place at the Edwards Air Force Base in California, USA, will be the culmination of 10 years’ work.

At 25 ft (7.6m) long, weighing just over three tons and using a ton of water every 25 minutes, Inspiration is no ordinary vehicle. When the car is moving, the 40 bar water pressure is maintained using compressed air to fill two 70-litre hydraulic accumulator bladders. The boilers contain more than 1.86 miles (3 km) of tubing and are insulated with advanced ceramic-and-silica cloth.

The burners develop three megawatts of heat that raises the water to 250°C, and because it is at 40 times atmospheric pressure it’s referred to as ‘wet’ steam. It is then super-heated to 400°C ‘dry’ steam, which is directed down the car via heavily lagged pipes and two industrial steam valves into a two-stage turbine.

The steam is injected into the turbine at more than twice the speed of sound and the turbine spins at up to 13,000 rpm. The turbine then drives the rear wheels, crown wheel and pinion reduction gear. The machine actually runs for less time than it takes start. It takes eight minutes to get going and has enough fuel, compressed air and water to run for three minutes – the record can be achieved in less than two minutes running time.

Speed build up

While the record is measured over a distance of one mile, the car needs a straight runway of almost seven miles in order to build up speed and then slow down. At the end of the first run, additional water has to be injected to carry on for the second run and then to cool down.

In order to generate the required stream pressure for a run, the steam car’s two 70 l hydraulic accumulator bladders, which feed the 12 onboard boilers, need to be carefully primed with demineralised water. The water is supplied from holding tanks located on two purpose-built ‘start’ and ‘turnaround’ rigs at a pressure of 40 bar. This essential task has been allocated to two 1520C triplex positive displacement plunger pumps from Cat Pumps, which feed the car at a rate of between 50 and 40 litres per minute.

The pumps have played an important role throughout the development of the steam-powered car, not just on the rigs but also on the test beds where the boilers have been designed. “When the car is running, all the steam generated must go to the wheels so there is a lot of accumulated power onboard,” says consulting engineer Matthew Candy.

“The design of the system means that the water must go seamlessly from the displacement to the car’s accumulator systems, as is it essential to have water in the boilers at all times, for if we lose the water the boiler tubes will fail very quickly. The Cat 1520C pump meets this requirement.”

CAT PUMPS

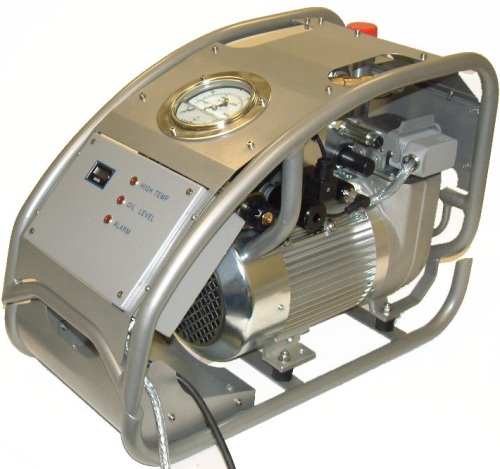

Cat Pumps’ 1520C model is a triplex reciprocating positive displacement piston type pump and is capable of generating pressures up to 70 bar. This type of pump takes in a fixed volume of liquid on each inlet stroke and physically moves it through and out of the pump with virtually no losses or inefficiencies.

Cat Pumps’ triplex pumps contain three synchronised pistons or plungers which produce a low-pulsation flow that is sufficiently smooth for most applications. The flow is highly stable and predictable because the flow rate is determined almost exactly by the running speed of the pump and is virtually unaffected by back-pressure, liquid viscosity or specific gravity.

Recognised for its reliable operation and ease of maintenance, this pump can be found in many situations where a continuous forward liquid flow is required for a smooth operation. A significant bonus for the steam car application is that is capable of handling the non-inherent lubricity properties of demineralised water.

Boiler development

The development of ‘Inspiration‘s’ boilers has taken several years, moving from an original plan of four units to a final complement of 12 units, and the 1520C pump has been used on the boiler tests for all that time.

“The versatility of the pump’s output has enabled all testing to be undertaken with just one pump,” continues Candy. “When powered by an electric motor in the boiler test cell we found the pump easy to control and highly sensitive to the task in hand. We were able to run the flow down to as low as 4 l/min in order to test each boiler.

For the next stage of the boiler development programme, we shall use a smaller unit for a new test cell. An electric motor is not feasible for powering the pumps on the rigs, so each of the pumps is powered by a Briggs & Stratton motor which does reduce the performance variability slightly, but with no detriment to the duty. The pumps are rugged, compact and come with a pressure relief system to take the bounce out of the flow.”

When considering the steam car development programme in its entirety, Cat Pumps’ 1520 C pumps are a relatively small component. That said, their input is critical to the success of the challenge during the start-up sequence for the first run and once again before the second run. The steam cannot be generated by the car’s boilers without the controlled high pressure inflow of water from the pumps and without steam at the right temperatures and pressures, Inspiration is a non-starter.